Stretch Broken Carbon Fiber (SBCF)

Advanced carbon fiber composites for complex, high-performance structures.

Background:

Traditional continuous carbon fiber composites offer excellent strength-to-weight and stiffness-to-weight ratios but are difficult and costly to form into complex shapes. Their rigidity limits design flexibility and often requires expensive manufacturing methods or hybrid assemblies with metals, leading to higher costs and corrosion issues. Chopped carbon fiber and carbon fiber sheet molding material grant formability but come with compromises to performance.

Stretch broken carbon fiber (SBCF) has long promised the formability of chopped fiber with the performance of continuous fiber, however widespread adoption has been limited by manufacturing challenges. Historically, inconsistent fiber breakage, poor alignment, and lack of scalable equipment resulted in reduced mechanical properties and limited production rates. Integration with standard composite processes also proved difficult, preventing SBCF from meeting the demands of high-volume industries.

Description:

MSU’s Stretch Broken Carbon Fiber (SBCF) technology dramatically improves the formability of carbon fiber composites by using short, aligned fibers (approx. 1.5 inches) while maintaining the strength of continuous carbon fiber. SBCF materials can be shaped into intricate geometries using standard composite equipment, enabling membrane stretching and deep draws not possible with conventional fibers. This eliminates autoclave requirements and replaces labor-intensive layup with rapid compression molding.

Two proprietary production methods - Direct to Prepreg (DTP) and Single Tow - support scalable manufacturing in both prepreg and tow formats. These can integrate with existing composite manufacturing processes.

Figure 1: Example of the complex shapes that can be achieved with MSU SBCF. This example exhibits complex and reverse curvatures and sharp features akin to deep drawing in metals.

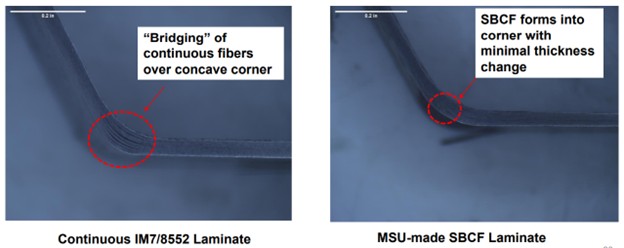

Figure 2: Side-by-side optical micrographs compare the cross-sectional geometry of composite laminates formed over a concave corner. The left image shows a Continuous IM7/8552 Laminate, where multiple layers of continuous fibers exhibit "bridging" and fail to conform tightly to the corner, resulting in visible gaps and increased thickness. The right image displays an MSU-made Stretch Broken Carbon Fiber (SBCF) Laminate, where the fibers conform smoothly into the corner with minimal thickness variation, indicating improved formability and reduced bridging. Both images include a 0.2-inch scale bar for reference.

Montana State University’s proprietary, scalable production methods and custom equipment deliver consistent fiber alignment and quality on a pilot scale and are currently operating at a TRL 6. MSU’s system is the first to demonstrate reliable, high-throughput SBCF manufacturing, validated in Army-funded trials and ready for industry adoption.

Illustrative Applications:

- Automotive

- Chassis Crossmembers: High-volume compression molding for fast cycle times.

- EV Battery Enclosures: Achieve high modulus at lower costs than continuous fiber.

- Consumer Electronics

- Ultra-Thin Device Chassis: Enable mobile phone chassis wall thicknesses unattainable with aluminum or continuous fiber.

- Industrial Robotics

- Lightweight Manipulator Arms and End Effectors: Reduce inertia for faster, energy-efficient automation.

- Aerospace & Defense

- Complex Airframe Components: Replace titanium in rotorcraft spars to eliminate galvanic corrosion and reduce weight.

- Engine Nacelles: Form intricate contours for next-gen turbofans.

Benefits:

- Up to 100x more formable than traditional carbon fiber, enabling deep draws and complex shapes without wrinkling

- Maintains high strength and stiffness

- Replaces metal substructures, reducing corrosion and simplifying design

- TRL 6: Validated in U.S. Army-funded trials

Opportunity:

- Technology with pending patents is available for license and commercialization

- Collaboration with MSU SBCF experts for application-specific solutions.

Further Information:

- Patents pending in the US US20230304195A1, Europe EP4204612A4 and Japan JP2023540039A.

- Recent SBCF presentations and publications.

Contact:

Nick Zelver

406‐994‐7706

nzelver@montana.edu

Daniel Juliano

406‐994‐7483

daniel.juliano@montana.edu